A light step towards the future

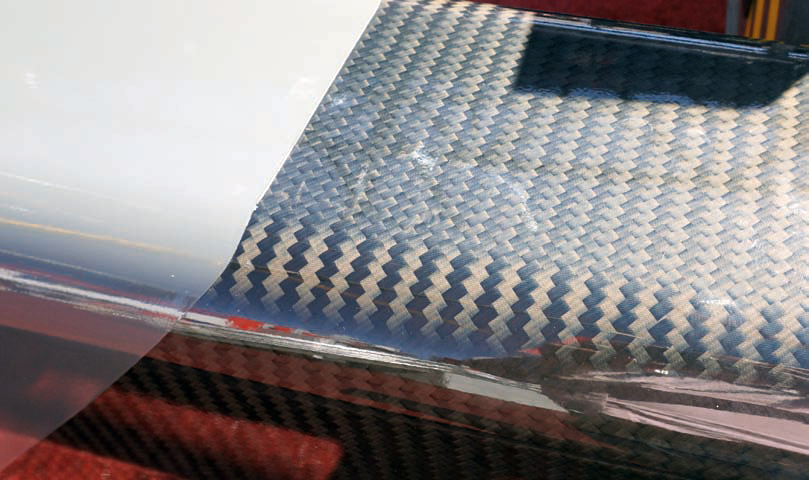

17 April 2017Manitowoc introduced synthetic rope on mobile cranes at ConExpo 2014. This year, the company showed another new use of materials, with a carbon-fibre-reinforced polymer (CFRP) fly jib. While other companies have previously offered CFRP as an option for pendants on tower cranes and crawlers, this is the first such application on a boom or jib component. Talking to John Benton, principal engineer for Manitowoc’s truck crane and all-terrain line, Will North finds out what this means for the future of cranes.

The launch of the CFRP fly jib, also known as a stinger, would have been easy to overlook. However, it brings with it the promise of lighter cranes, with much improved capacity.

The CFRP stinger has been developed over many years by Manitowoc. It was first offered, Benton says, as an option for buyers of the RT 990E rough terrain.

ConExpo 2017, where it was offered with the new TMS 9000-2, was, however, its first public showing.

“It’s an option for customers who are in a very weight-critical situation,” Benton says. “This is one of the best options that we have for reducing weight on the front axles of our four-axle truck crane.

“It brings the advantage of being able to reduce weight, and still keep some of the other advantages of our new boom extension system. We have an integrated heavy-lifting jib that can be built in as an option that adds some weight, and using this with it offsets some of that weight.”

“As the CFRP stinger is the farthest piece of the crane in a lifting situation, almost all of the weight that is saved there is able to be used for weight on the hook.”

That weight saving means that customers may be able to take on jobs using a crane with the stinger that they could not with a traditional steel fly jib.

The 24.22ft (7.38m) stinger weighs just 470lb (213kg). A comparable steel component would, Benton says, weigh over 600lb.

“There are two ways to look at that, Benton says. “One is to say it’s only a few hundred pounds.

But if that’s the difference for the customer between being able to carry the components they need with them to make their job and not being able to carry them, then it really becomes the logical choice for them to make. And in percentage terms, you can see what that could mean in the future as the technology moves to more of the structure.”

Benton would not detail Manitowoc’s development plans, but indicated that increased use of new materials like CFRP could play a part in future crane designs.

“It’s something that could find other applications, not just as used here on the fly jib. The thickness of carbon-fibre components is one of the really challenging aspects.

The thicker they become, the more difficult they are to manufacture.

There are still some technical challenges ahead of us as an industry. But it could be used in other boom components as well.”