Working within tight limits

17 August 2017Mobile cranes can now calculate real time loading for a full complement of outrigger positions,maximising capacity and improving safety. Bernadette Ballantyne reports.

It is a beautiful summer day in central London, and a Liebherr LTM 1130-5.1 all terrain crane, owned by Southern Cranes & Access has just placed a 2t section of a new staircase inside a five-storey office building. The commercial property is undergoing major refurbishment and the staircase is one of the final elements of the job.

To undertake the project, the crane is sitting outside on the street in front of the building, its outriggers are 100% fully extended on the left-hand side, and 60% short rigged on the right. Like many city centre projects one lane of the highway must remain open throughout crane operations, meaning that full extension of the right-hand outriggers is not possible.

In the past, this would have meant operating the crane according to the predetermined load charts assuming a limited extension of the outriggers, probably 50%. But a huge disadvantage of this was that the crane lost out on capacity that it actually had, resulting from the full extension on the left.

Aware of this issue Liebherr invested in the creation of the VarioBase system seven years ago, revealing it at Bauma in 2010. This measures both the extension length and pressure in the outriggers and uses the crane rigging information inputted by the operator before calculating the actual crane capacity in real time.

“Without VarioBase we would have had to use a larger crane further down the road, which means we wouldn’t have been competitive on this job,” explains Ross Wickens, sales and technical manager for Southern Cranes, and a former crane operator himself.

The set up was further limited by the presence of basements along the road meaning that pressure could not be exerted over the pavement.

“The sensors within the outrigger talk to the computer which lets the operator know where it is, what rig is where and the pressure going through each outrigger and what the crane can do. If he tried to come this way his computer will tell him how much that outrigger is out and how much weight he can lift, as it will obviously come down as you go around the crane,” Wickens says pointing to the side where the outriggers are at 60% extension.

The 130t crane is set up with 42t of counterweight and two rope falls. “At the moment, I am at 45°,” explains the crane operator Ryan Whitfield. “It is a telescopic boom with five sections, 60m in total.”

In order to lift over the existing building the crane boom is fully extended. “I have full counterweight, yesterday I had three falls of rope and now I have two. They each have 8.4t capacity per line pull. Yesterday’s job was over 20t,” explains Whitfield.

“The sensors are automatically on. With the new computers, they acknowledge where the outriggers are so you can’t lie to it or put yourself in a position where you might make a mistake,” he says.

Improving safety was one of the reasons that Liebherr developed VarioBase, which comes as an option on its LICCON 2 operating system. The system identifies the machine’s precise centre of gravity and the tipping edges and then sets the two relative to each other. If a load is lifted over one support, the risk of tipping is lower than a lift to the side. This means that the system can allow a higher load capacity and a greater outreach. The greatest increases are in working areas above the supports when partial ballast is in use. Load capacity increase also means that sometimes full ballast is no longer needed.

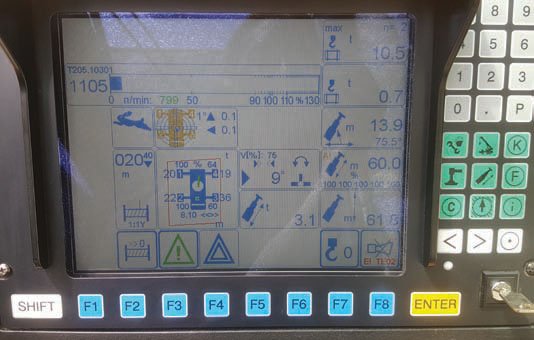

“The crane control (LICCONSystem) calculates the load chart in real time, not using stored load charts,” explains Patrick Fähnle, technical trainer at Liebherr. “It is totally up to date because we have the length of the sliding beams, and the pressure of the support cylinders. It adds eight more sensors, four on each support cylinder and four to measure length. It is very safe,” he adds. The system tracks the capacity as the machine is slewing, so if lifting begins to approach the ultimate capacity, the crane will slow and cannot continue to be moved once the limit is reached. The LICCON 2 system itself was introduced in 2007, building on the success of LICCON 1. “We got to a point where the storage capacity was not enough for the new bigger cranes which have more configurations, more boom extensions, so the load chart data was growing and growing. We designed LICCON 2 with new architecture that would be suitable for the future,” says Fähnle.

Fundamentally the new LICCON 2 system combined the processing power of the PC with the screen in a single unit. “The monitor is now not only a screen, it includes the complete PC inside. Processor speed gets faster every year. We have a bigger memory card inside with much higher storage capacity than before,” he says.

Another major advantage of the LICCON 2 is that it comes with a work planner that allows operators to simulate the lift before they start work.

This was something that Southern Cranes found very useful in preparing for its confined London lift. Lifting in the city

Another company that sees the benefits of crane control systems that offer enhanced load monitoring and the ability to accurately assess true capacity under a range of outrigger scenarios is Belgium’s Sarens. In March it was announced that the firm would purchase 18 new Demag AC cranes which are fitted with the firm’s new IC-1 Plus system.

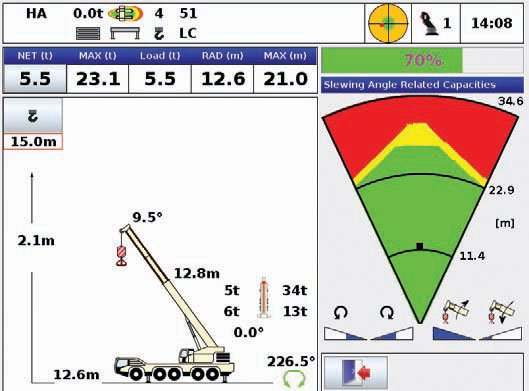

“Our IC-1 Plus system now allows outriggers to be set arbitrarily to get true configuration as your space constraints on the job site allow the extension. The system now onboard gives you charts for the capacity of the crane, for that configuration, and it is now slew angle related,” explains Ascan Klein, director, competence centre control systems at Terex Cranes.

“We monitor how the crane is set up,” he says explaining that sensors measure the outrigger position, and the amount of installed counterweight. Other data such as the boom configuration and reeving is entered by the operator. “Based on this data we have algorithms releasing the optimal capacity at the actual point of operation.” This means that the operator can optimise the crane capacity at every lifting point with arbitrary outrigger settings. Even when set on a standard outrigger base the slew angle related capacities are significantly improved compared to the classical 360° charts.

In addition the operator has a planning tool on board, which is embedded in the operator display but can also be used as a remote web based applicaton, which shows, depending on the outrigger settings, which capacity can be reached at a given point.

The seamless integration of this technology into the well-known, easy to operate IC-1 control system provides the operator continuously with an overview of the actual lifting situation and its surrounding.

So far the IC-1 Plus is available on all new AC cranes. It can also be retrofitted on to some models, but this has to be assessed on a case by case basis. Over time the firm plans to extend this across the Terex crane range.

“Customers from urban areas are excited about it. Wherever you work in confined spaces our customers really appreciate it,” says Klein.

This is certainly true for Sarens which has just purchased eight AC 100 4L cranes, seven AC 220- 5, and three AC 130-5 cranes.

Group equipment trade manager Jan L Sarens, says: “We have had a very positive experience with these cranes in the past. What we see now is that these are very operationally effective and cost efficient. Specifically, what we like about the IC1-Plus system is that it is good for city use.

“A lot of the cranes we have recently purchased are going to be used in London, so for city use it is a real big advantage because there is not always room to have outriggers fully out.”

He echoes the experience of other crane companies who find that the monitoring facility enhances capacity. “When the outriggers are out, you are not automatically downgraded to the load charts where they have 360 degree operation and that is really a very big advantage in those cases where you lose capacity compared to the full outriggers.”

The other big advantage for Sarens is safety. With over 1500 cranes in its possession including some with Liebherr’s VarioBase system this is paramount.

“The system is obviously to enhance safety. You can train people as much as you want and have much experience but in the end people can make mistakes,” he says explaining that the live load monitoring based on the actual outrigger positions prevents operator errors.

A mistake made by mobile crane operators in the past has been to assume full load capacity when one or more of the outriggers are only partially extended, manually overriding the safe working load system.

Although this was somewhat addressed under EN1300 and the removal of the override mechanism from the cabin, live load monitoring with the full range of outrigger positions is another useful step.

“When we buy a new crane now we take it as standard, VarioBase or IC-1Plus. Manufacturers offer it as an option but internally we decided to take it as standard because we see it as a safety feature,” says Sarens.

“The additional cost compared to the basic price of a crane is rather limited. We have to do it. We decided to make it default, for us it is not an option. Every system that can help the operator do his job safely is a big advantage.”

Crawling forward

For Link-Belt Cranes, operator mobility is an advantage of the V-CALC system, which is standard on its Pulse 2.0 crane control system. Introduced at ConExpo this year, V-CALC stands for Variable Confined Area Lifting Capacities.

Brian Smoot, project manager for telescopic rough terrain cranes at Link-Belt, said: “The operator can now set his outriggers into various positions and get different capacities based on where his boom is in relation to the outriggers.

“With that there is a function to alert him to an area where there is less capacity and start slowing his function down to come to a smooth stop before he gets to that specific point.”

So far the system has been introduced to one new crane model, the 75|RT rough terrain crane. “With our standard CALC system, the crane capacities are set based on the most retracted outriggers. Now with the V-CALC, you get the capacity for the intermediate distance,” adds Smoot.

“Before the operator starts lifting he can put in the configuration and go to a preview screen which will tell him what his capacities are good for in each one of the quadrants, and another screen will show him what his capacity will be for the next five radii as well.

“If he is good with that set up he can go to the live working mode. It will actually alert him if he starts to swing over to the area carrying too much capacity and automatically start slowing down. His load doesn’t come to an abrupt stop; it is a good smooth stop.”

The TCC-2500 which debuted at ConExpo also features Pulse 2.0 with its ten inch touch screen display, increased diagnostics, and user friendly navigation.

“I love the machine, I really do,” says Jamie Foster, an experienced operator for L.R. Willson & Sons. The company has been field testing the TCC-2500 machine for several weeks using it for tilt panel work and steel erection.

Foster spoke to Cranes Today from the cab of the crane where he explained that the control system has made life easier for the operator.

“It tells me how high my boom is in the air, how much boom I have out, my boom angle, and how far away I am. Right now I am at 64ft at 63°. I am good for 22,400 lbs with 151.3 feet of boom out,” he says.

“The crane’s multiple list charts were a big help when it came to lifting the tilt panels. The system alerts you if the crane is out of level and then by selecting the appropriate list chart Pulse 2.0 compensates by calculating the new capacity. This is something I have never seen before. Never seen it compensate the weight for how much you are out of level. If I am dead level I can pick up 20,000lbs. If I am 2° out then it will tell me I can only pick up 16,000lbs.”

Self-assembly too is easier says Foster, who has been urging his company to invest in the machine once the testing period is over. The machine calculates capacity as the machine is assembled, so every time new components are added the computer adjusts the capacity limits.

“Every time you put a track on, you update the computer and it tells you how much you can do then. Put the second track on and two crawler body weights and your capacity increases - the computer can basically monitor and adjust through the entire assembly process.”

The general functionality of Pulse 2.0 has made the most lasting impression. “The best thing about it is that the computer shows you everything and it is all touch screen. Once the computer is setup correctly nothing should ever go wrong,” says Foster.

The new Demag AC 300-6 all-terrain crane, comes with IC-1Plus and has an 80m (262.5ft) main boom. It is the first crane of its size in the Demag range equipped with a luffing jib.

The new Demag AC 300-6 all-terrain crane, comes with IC-1Plus and has an 80m (262.5ft) main boom. It is the first crane of its size in the Demag range equipped with a luffing jib.

The Pulse 2.0 control system on the TCC-2500 from Link-Belt, launched at ConExpo, automatically adjusts capacity depending on how level the ground is.

The Pulse 2.0 control system on the TCC-2500 from Link-Belt, launched at ConExpo, automatically adjusts capacity depending on how level the ground is.

With Demag’s control system, the operator can clearly see the actual capacity at the range of slew angles based on outrigger set up

With Demag’s control system, the operator can clearly see the actual capacity at the range of slew angles based on outrigger set up

The crane with outriggers extended at full capacity on the left hand side, and at 60 percent extension on the left

The crane with outriggers extended at full capacity on the left hand side, and at 60 percent extension on the left

The user friendly display shows the safe working load of the crane based on the set up of the crane, including the outriggers.

The user friendly display shows the safe working load of the crane based on the set up of the crane, including the outriggers.