LTM 1110-5.2 debuts Liccon3 crane control

8 December 2021Gen 3 of Liebherr’s Liccon crane control system launched on LTM 1110-5.2 all terrain.

Liebherr has updated its LTM 1110-5.1 all terrain crane in three key areas – the crane control system, the driver's cab, and the gearbox – to create the LTM 1110-5.2. It has undergone intensive testing and is now ready for series production.

Liccon3 crane control

The crane marks the launch of the third generation of the Liebherr’s Liccon crane control system. Liebherr said this comprises a new software package, a new programming language, a faster databus, plus more storage space and computing power.

The system’s hardware components include a BTT remote control terminal and a touchscreen function on a new large display in the superstructure cab. The way in which the information is shown has also been revised and simplified. Liccon3 cranes are also prepared for telemetry and fleet management systems as standard, said Liebherr. In the future, crane contractors will be able to view and evaluate all the relevant data using the MyLiebherr customer portal.

Nikolaus Mu¨nch, head of the control system department at Liebherr in Ehingen, said, “During the development of the new control system it was important to us that crane operators who are familiar with Liebherr cranes would be able to get used to the new control system quickly and easily. At the same time we must be future-proof as the progress currently being made in microelectronics is immense. Complex applications, such as VarioBase, which require a great deal of performance data, can now be developed more frequently in the future. The current Liccon2 control system is reaching the limits of its capacity.”

Driver’s cab

The new driver's cab, an initial version of which was unveiled at Bauma 2019, was designed in collaboration with designer Ju¨rgen R. Schmid of German design company Design Tech. According to Liebherr, improvements for the crane driver include a new multifunction steering wheel, a side roller blind on the driver’s door, improved instruments and modules, as well as new displays. Options include a central locking system with remote key, a cool box, and a tyre pressure monitoring system.

The cab has a new automatic heating and climate control system in both the driver’s and operator’s cabs. A sun sensor detects strong sunshine and automatically adjusts the heating settings. In addition to the standard radio with hands-free facility, a double DIN radio with extended functions is available as an optional extra.

The lighting packages for the crane cabs, the superstructure, the rear of the vehicle, the front headlights and the telescopic boom and lattice jibs have been improved and now feature LEDs.

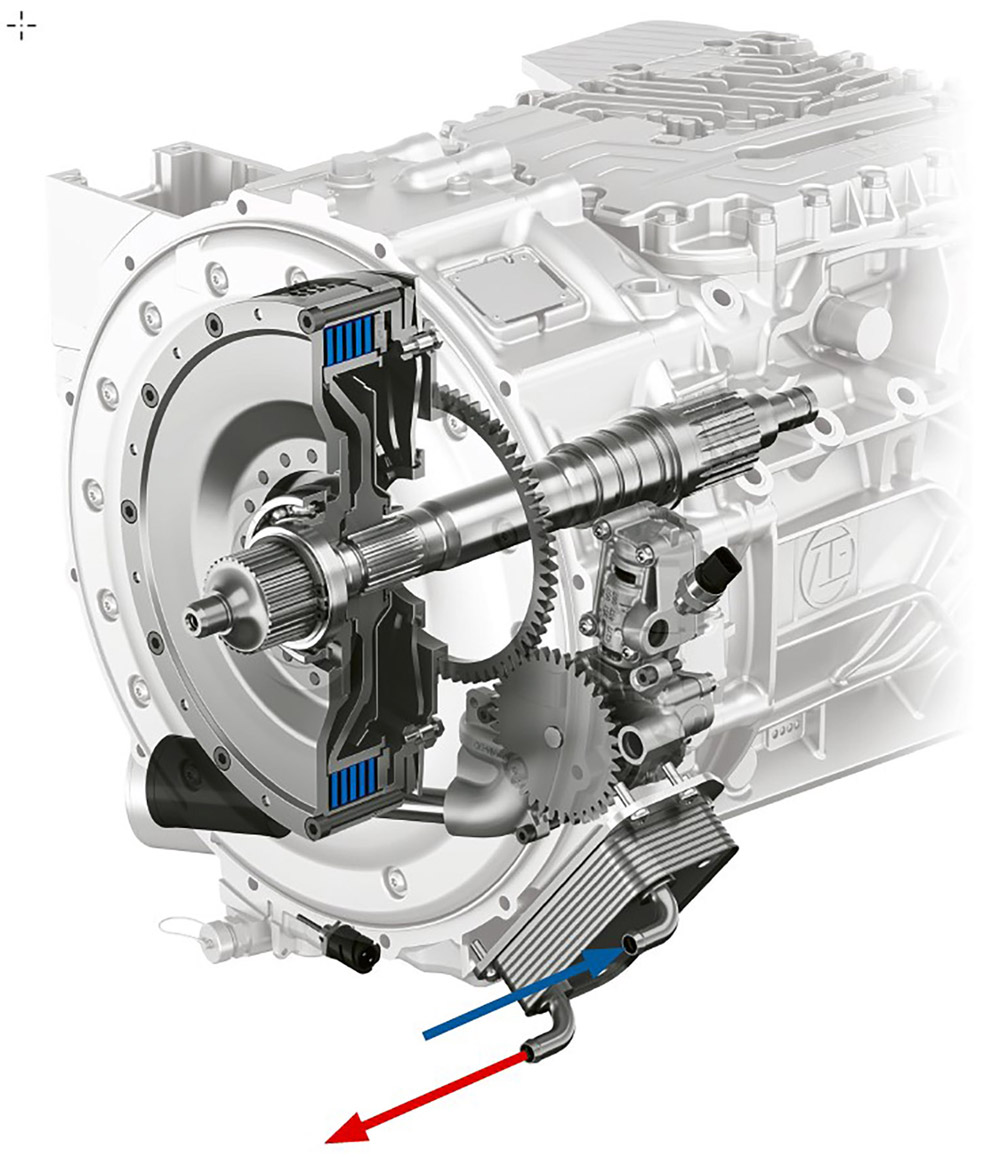

Gearbox with oil-cooled clutch

The modular ZF TraXon gearbox has a new oil-cooled DynamicPerform clutch module which Liebherr said is highly resistant to wear or overheating.

Liebherr plans to install the DynamicPerform clutch in its five-axle mobile cranes on a step-by-step basis. On mobile cranes with six or more axles, Liebherr intends to continue to use the ZF 12-speed TraXon Torque gearbox with starting converter.