Self erecting tower cranes offer fast and easy setup in a compact, mobile format. With less support requirements than traditional tower cranes, the crane type can be a key tool for contractors looking for a cost-effective jobsite solution thanks to lower installation and dismantling costs. What’s not to like?

In Europe, in particular, the residential housing sector is a key application area in which contractors extensively use self erectors. The cranes’ mobility, compact footprint, and fast assembly/disassembly make them, along with smaller telescopic cranes, a popular choice for this type of work.

And despite Germany, a key European market for manufacturers of self erecting tower cranes, currently being in recession (due to high interest and inflation rates combined with political uncertainty) the wider consensus is that – with continuing population expansion across Europe (and beyond) – the need for more housing will inevitably continue.

Add to this the expanding popularity of self erectors in new markets, this crane-type sector looks to be in a secure position. As such, manufacturers are developing new products and there’s a range of new metal on the market.

NEW METAL

Marking the start of the ‘construction season’ across large parts of Europe (as harsh winter weather subsides) German fullservice provider of crane solutions BKL Baukran Logistik has just launched the CM 301 self erector.

The crane is aimed squarely at the residential construction sector with BKL saying it has been ‘especially designed for carpenters and roofers’.

It has been developed in conjunction with Italian crane manufacturer Luigi Cattaneo. BKL first launched the BKL System Cattaneo brand as exclusive distributor for Germany and Austria in 2012 and there are now seven bottom-slewing self erecting cranes in the BKL System Cattaneo portfolio, three of which being mobile self erecting roofing cranes.

The latest of these roofing cranes, the CM 301, offers a 20.7-metre hook height, a 30-metre radius, and a maximum lifting capacity of 2.5 tonnes. It can lift 600kg at the tip of its boom.

The crane’s two-fall technology also enables a higher handling rate, BKL adds.

In addition to the CM 301’s optimised assembly/disassembly, to further optimise fast transport between job sites the crane has a 25 km/h axle, with the option of specifying an 80 km/h axle if required.

The CM 301 also has a combined drawbar with king pin. This allows for transport as a trailer crane or as a semi-trailer. For projects without a site power supply, the crane can also be operated with 230 V.

The CM 301 is now available to rent or purchase from BKL. It currently has an ‘all inclusive’ purchase price starting at €116,000, plus VAT. This includes BKL’s three-year quality warranty, support pyramids, remote control, delivery and initial assembly within Germany.

The other two mobile self erecting roofing cranes in the range are the CM 221A, with a radius of 22 metres, a hook height of 17.3 metres, and a maximum lifting capacity of 1.8 tonnes, and the (optimised) CM 271, with a radius of 27 metres, a hook height of 20.5 metres, and a maximum lifting capacity of 2.5 tonnes – making the new CM 301 the range leader of these three.

GLOBAL DEBUT

Making its debut to global audiences at Bauma 2025 is the Potain Igo M 24-19 self erecting crane from USA-headquartered global crane manufacturer Manitowoc. It officially launched at French trade show Batimat, in Paris, France, late last year but the Bauma show will be the first time many international visitors will get to see it.

The Igo M 24-19 succeeds Potain’s top-selling Igo M 14 and is also squarely aimed at builders and carpenters due to its suitability for new home construction and renovations.

The new model has a compact design, measuring 11.83 m in length when folded, allowing it to access narrow jobsites.

For versatility the Igo M 24-19 has three jib configurations: 12.3m, 21m, and the full 24m.

It comes with permanent ballast installed and has three steering axle options for travel: a 25 km/h tow bar; an 80 km/h tow bar; and a fifth wheel.

With a maximum capacity of 1.8 tonnes, the crane can lift up to 570kg at its maximum jib length of 24m, and it has a hook height of 19m. Additionally, it can operate in a raised jib position of 11° or 20° for increased height under the hook when needed.

LATEST UPGRADES

The new Igo M 24-19 includes the latest upgrades for Potain self erecting cranes. These include: Smart Setup, with remotecontrolled guidance for automatic folding and unfolding of the crane; Potain’s Crane Control System (CCS), which is designed to maximise lifting performance, improve operator ergonomics, and increase jobsite flexibility; Drive Control, designed to give control and precision lifting; Power Control, with an adaptable power supply; and a Steering Axle to enhance manoeuvrability.

The crane also includes the Potain Connect telematics system, which provides remote diagnostics, advanced analytics, and fleet management information designed to maximise uptime and optimise crane utilisation.

There are other productivity options too, including an onboard generator for power independence on jobsites, hydraulic levelling for simplified crane setup, Potain Plus load curve software that enhances load chart capabilities, and the Top Site working range limiter.

“We can’t wait to reveal the Potain Igo M 24-19 at Bauma 2025 and give it its global debut,” said Rémi Deporte, self erecting cranes product manager at Manitowoc.

“This crane is all about enhancing compactness, mobility, performance, and productivity, ensuring our customers get the most out of their investment.”

At Bauma 2025 the new Igo M 24-19 will be showcased alongside one of Manitowoc’s best-selling self erecting tower cranes: the Potain Hup M 28-22 A. Since its launch in early 2020, Manitowoc claims this model has quickly become a customer favourite across Europe.

The Hup M 28-22 A can lift up to 2.2 tonnes and handle up to 850kg at its jib end. Manitowoc says it’s the only self erecting crane with a 28m jib capable of achieving hook heights from 19.6m to 31.1m with such a compact transport format. With travelready dimensions of 11.6m in length and 3.6m in height, it can be transported by a standard truck and easily pass under bridges.

The crane’s permanently attached steel ballast allows it to be transported as a trailer or semi-trailer. A TÜV-certified integrated transport axle enables road travel speeds of up to 80 km/h, and a +20°/-20° maximum steering radius provides access to even the most restricted jobsites.

GET CONNECTED

The crane also features the Potain Connect telematics system.

Potain’s Smart Setup and the Hup series’ remote-control software are designed to make the crane easy to erect and dismantle.

Mechanisms on the crane include DVF Optima for trolleying, LVF Optima for lifting, and HPS for slewing.

“Our Potain Hup M 28-22 A is known for its versatility and reliable performance,” adds Deporte. “It’s an advanced, reliable, and versatile jobsite tool and has helped countless customers throughout Europe and the rest of the world complete their projects with maximum efficiency.

“Owners and users love it for its efficient transport, quick setup, and flexible configuration options, making it a go-to crane for all types of projects.”

NEW LOOK, NEW CRANE

Also showcasing a new self erector to a global audience for the first time is Dutch self erecting tower crane pioneer Spierings.

At Bauma 2025 it will premiere the five-axle SK1265-AT5 eLift. The crane has already debuted at an exhibition in Southern Europe but Bauma will be first opportunity for broader (global) exposure.

Full details of the new crane will be available to visitors to Spiering’s stand at Bauma (Stand FS1002/1), although the company has revealed that the SK1265-AT5 eLift combines maximum lifting capacity with a compact undercarriage and minimal environmental impact offering broad usability across various applications.

At Bauma the crane will be showcased in a twice daily live demonstration (at 11am and 3pm) throughout the week.

In addition to this new crane, other new Spierings innovations will also be on display at Bauma. One of these focuses on enhancing operator comfort and ease of use. To find out more Spierings encourages showgoers to visit its stand.

And if you do go to Spierings’ stand, you might notice something different: the company is using Bauma 2025 as a launchpad for a rebranding. The new company look is designed to highlight the company’s approach to emission-free lifting, encapsulated in the slogan ‘Mission to Zero-Emission’.

To complement the company’s rebranding it has also just launched a completely redesigned website which went live at the end of March.

While the visual identity has been given a modern touch, says Spierings, it remains true to the company’s core values of innovation, sustainability, userfriendliness, and loyalty.

It says the refresh symbolises Spierings’ strategic direction: although the appearance is evolving, the Spierings spirit remains the same: personal, accessible, and ahead of the curve.

FUTURE-READY

Liebherr will also use Bauma 2025 to showcase the latest upgrades to its established range of K series bottom-slewing, fast-erecting cranes making them, what it describes as, ‘future-ready’.

The new models, the 43 K, 61 K and 91 K succeed the 34 K, 53 K, 81 K.1 respectively, while there is also Additio

All, apart from the 125 K, receive performance boosts. The 43 K, for example, has two more metres of radius, four more metres of hook height, and its maximum jib head lifting capacity has been increased by 200kg compared to its predecessor.

Similarly, the 61 K now offers three metres of additional radius, a 2.4 metre higher maximum hook height, and up to 200kg more jib head lifting capacity.

Helping facilitate these increases, and cementing the cranes’ ‘future-ready’ status, is the availability of Liebherr’s latest suite of intelligent assistance systems.

All the new K cranes come with Liebherr’s latest control and operating systems. This means Liebherr Control 5 for the crane control system and Tower Crane Operating System 2 (TC OS 2) for the operating system.

The control system is robust and durable, says Liebherr, as demonstrated by the current L series of fast-erecting cranes in which it is also installed.

The control system is also utilised in a variety of other construction machines within the Liebherr Group.

The TC OS 2 has a standardised menu navigation which, Liebherr says, is intuitive via its use of selfexplanatory symbols and icons. It also has a standardised radio control (standard across all cranes in the current K and L series).

INTELLIGENT THINKING

But what does the adoption of the new control and operating system in the upgraded K Series cranes mean for crane operators?

It means enhanced operator assistance as there are now five intelligent assistance systems available (also now available on Liebherr’s L series bottom-slewing cranes, too).

This is largely thanks to the control system’s high processing power which enables all assistance algorithms to be processed in real time. A batterypowered IMU (Inertial Measurement Unit) sensor system measures hook inclination and angular velocity, while a sensor system on the tower detects the inclination of the tower.

ASSISTANCE SYSTEMS

Sway Control is included as standard with all cranes; the other four, Sway Control Plus, Guided Hook, Vertical Line Finder and Positioning Pilot, are all optional.

The Sway Control Plus assistance system is designed to support the crane operator with sway-free operation by actively correcting hook block sway in both slewing and trolley directions. A sensor system also recognises sway that already exists before the system is activated or is caused by external influences, such as wind. According to Liebherr, this assistant is particularly beneficial for occasional crane operators who have sufficient space, and for new crane operators as less training is needed.

The Guided Hook assistance system means an operator on the ground is able to move the hook by hand and so guide it to the load themselves. The hook can be moved in slewing and trolley directions. This means constant communication between the crane operator and ground operative is no longer necessary, says Liebherr, reducing the likelihood of errors or misunderstandings and so increasing efficiency and safety on site.

The Vertical Line Finder supports the crane operator with the lifting of loads by preventing diagonal pull, and therefore sway, when lifting. The crane automatically controls the slewing gear and trolley to ensure that the load hook is always optimally positioned above the load’s centre of gravity. As a result, the load is always lifted vertically, without any sway, which increases safety for people and sensitive components on site. For a Cranes Today video of the Vertical Line Finder in action (on a 33 L fast erector) see here: https://shorturl.at/jMcwI.

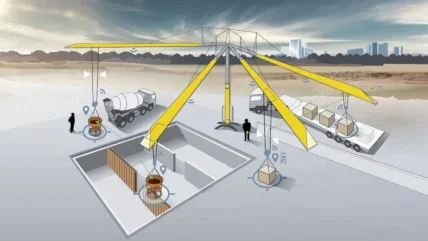

The Positioning Pilot assistance system makes it possible to move the hook to saved points semi-automatically and to follow predefined routes. Up to three hook positions can be repeatedly and accurately accessed as required and two individually mapped routes can be navigated. The routes can be travelled forwards and backwards, and stopping in between is also an option. This makes Positioning Pilot well-suited to repetitive, monotonous lifting tasks like concreting work and truck unloading processes that require several lifts. These semi-automated movements are carried out without sway.

Already established features, such as variable hook heights and manoeuvrability in tight spaces, continue to be part of the new series along with the familiar functions Speed2Lift, Load-Plus and Micromove for maximum lifting speeds, increased jib head lifting capacity and precise positioning of loads. The crane names now reflect the lifting capacities according to Load-Plus.

As Bauma 2025 approaches the self erecting crane sector is demonstrating its resilience and innovation. Despite economic challenges in key markets, manufacturers continue to refine and expand their offerings, with a clear focus on mobility, efficiency, and advanced technology.

As demand for faster, more adaptable lifting solutions grows the latest generation of self erecting cranes is well-positioned to meet the evolving needs of the construction industry.

JOHN SUTCH CRANES SPEAKS ABOUT ITS SPIERINGS SELF ERECTING TOWER CRANES

“We got our first Spierings self erecting tower crane around 20 years ago,” says Hayley Sutch, (designate) director at UK crane hire specialist John Sutch Cranes. “Us and City Lifting were the first in the UK to have them. I think Trevor Jepson [owner of City Lifting] was involved with the design and manufacture of them and it was Trevor and my dad who had the first ones over here.

“We now have two six-axle Spierings SK1265-AT6 cranes in our fl eet; they’re real stars of the show. We use them a lot to lift things like roof sheets and air conditioning units. Because the cab is up high the operator can see onto the top of buildings and pinpoint exactly where they are placing items – so it’s great for that type of work.

“When it comes to the self-erectors we’ve always stayed with Spierings. There are alternatives, of course, but we like the Spierings ethos and, like us, they’re a family business so we get on really well them.”

SCHILLER APPOINTED PRESIDENT OF UPERIO NORTH AMERICA

In November 2024 the North American division of the Uperio Group appointed crane industry veteran Ingo Schiller as President.

The Uperio Group is a provider of tower crane solutions offering tower crane sales, rental, and related services. It also manufactures its own line of Arcomet self-erecting tower cranes and the Opti crane aimed at contractors, roofers and carpenters. Schiller brings more than 30 years of experience in the crane and construction industry and is now responsible for strengthening the Uperio Group’s market position in North America via the expansion of strategic partnerships and development of new customer solutions. “We are delighted to welcome Ingo Schiller to lead our North American operations. His deep industry knowledge and proven leadership abilities align perfectly with our mission to provide lifting solutions and deliver exceptional value to our customers,” said Sébastien Desreumaux, CEO of Uperio Group. “We are pleased to welcome him and look forward to continuing to build together on the success of Uperio North America.”