Power generation is in a state of transformation. Old infrastructure is being dismantled, new systems are rising in their place, and sustainability is becoming a driving force. Behind the scenes, heavy lifting and rigging specialists are playing a vital role in keeping the lights on and the transition moving. From precision lifts in nuclear facilities to high-risk dismantling operations in storm-hit regions, the following projects showcase the critical contribution of lifting in the energy sector.

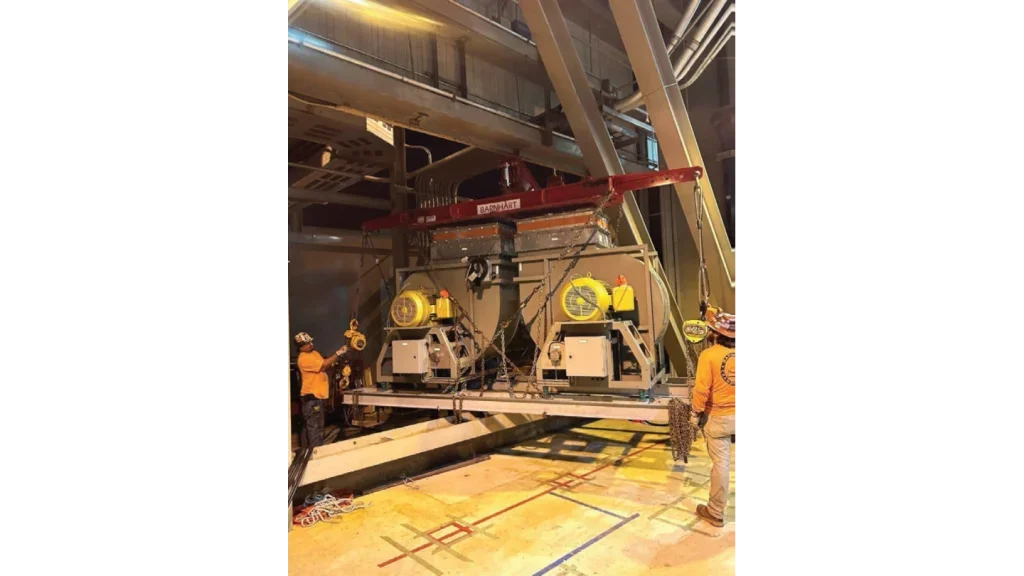

A power station lifting project earlier this year won US lifting, heavy-rigging and hauling specialist Barnhart an award from the SC&RA (Specialized Carriers &Rigging Association) – a USheadquartered international trade association for the specialised transport, lifting, and rigging industries. It was in the ‘Less than $300,000’ category and was for an elegant solution from Barnhart’s engineers for a complex ‘remove and replace’ job that included disassembling and removing an existing isophase fan at a powerplant and replacing it with three sections that had offset centres of gravity.

To achieve the lift innovations were made to Barnhart’s custom Tipstick. The Tipstick is designed specifically to upend smaller diameter vessels and pass them through narrow openings; it is a beam that attaches lengthways to the vessel and which has lifting points welded at intervals along it.

In normal use it raises the vessel from a horizontal position on the ground to hang nearvertically from the crane hook. Thus it eliminates the need for a tailing piece.

The Barnhart team modified an existing 27K Tipstick to accommodate the fan sections, each of which had an unknown centre of gravity, to minimise the required headroom.

The Tipstick was used in conjunction with several customised rigging and lifting tools, including Barnhart’s proprietary Movable Counterweight Cantilever System (MOCCS), a 75-ton Lift Systems Mobilift, a 100-ton slide, and multi-lift jacks for both removal and replacement.

With the help of these the vessel was manoeuvred through a narrow opening in the plant wall and set into position. The job was completed on time and within budget over a period of three days.

DEEPWATER DECOMMISSIONING

Moving further south, and offshore, global technical solutions provider for energy and infrastructure assets EnerMech has been awarded a contract by American multinational oil and gas corporation ExxonMobil to deliver a complete flowline decommissioning package for the Hoover Diana development in the Gulf of Mexico. The milestone scope marks EnerMech’s first major decommissioning campaign in the region.

The Hoover and Diana fields are located approximately 160 miles south of Galveston, Texas, and have been a landmark offshore development since 2000. The project uses the oncepioneering floating production deep draft caisson vessel technology and gained the world record for deepwater drilling and production depths.

Decommissioning a deepwater structure requires meticulous planning and execution. EnerMech carried out early proactive collaboration with ExxonMobil to ensure that its comprehensive approach is optimised for safety, efficiency, and regulatory compliance.

A team integrating multiple service lines from EnerMech’s Energy Solutions division will be deployed. It includes expertise in coiled tubing, pressure pumping, chemical services, filtration, separation, and pipeline gauging.

The scope includes flushing, pigging, and filling subsea pipelines to safely remove hydrocarbons and prepare for decommissioning. Nitrogen flushing is also involved, via a subsea vessel; there will be final seawater filling for the Northern Diana flowline.

“The Hoover-Diana project marks our first large-scale decommissioning engagement in the Gulf of Mexico,” says EnerMech CEO, Charles ‘Chuck’ Davison Jr. “Executing a multiservice end-of-lifecycle project of this scale requires a highly skilled and competent workforce.

“Securing this new contract following a competitive tender is a testament to our deep expertise, integrated capabilities, and the trust ExxonMobil continues to place in our team. Our early engagement has allowed us to develop a tailored methodology that maximises efficiencies, minimises risks, and ensures a safe, cost-effective execution.

“With many offshore assets reaching the end of their lifecycle, the decommissioning market in the Gulf of Mexico is expanding rapidly. This project underscores the value we bring to our customers and positions us for future growth in this critical sector.”

Jon Felton, EnerMech’s technical solutions director for the Western Hemisphere, added that the ability to seamlessly coordinate the multiple service line disciplines required simultaneously under one contract was crucial. “We have engineered a methodology that not only meets ExxonMobil’s expectations but also establishes a new benchmark for efficiency and safety in deepwater decommissioning,” he says.

NUCLEAR POWER

Moving north to Canada, and back onto land, Netherlandsheadquartered heavy lift and transport specialist Mammoet has conducted a considerable heavy lifting task for the power sector by placing eight steam generators into Unit 3 in Canada’s only private sector generator of nuclear energy Bruce Power is conducting a ‘Life- Extension Program and Major Component Replacement’ (MCR) project at its plant in Ontario.

The lift took place in February and marked a major milestone in the project.

The generators were large; in fact, Mammoet, no stranger to large lifts, described them as ‘hulking.’ The lift was capped off in February with the steam drum being set atop of the row of generators.

Ontario’s electricity needs are forecast to increase by as much as 75 per cent in the coming years. The Unit 3 MCR outage programme began in 2023. It remains on track as the company and its partners look to return the renewed unit to service in 2026 to provide clean and reliable electricity for decades to come.

Over the past six months, Bruce Power and the Steam Generator Replacement Team (SGRT) – a 50/50 joint venture between Aecon and SGT – have orchestrated the lifting of these massive, 100-tonne generators out of the Bruce A station through the roof, then lifting the new ones back in.

Mammoet’s towering PTC-35 crane, which stands more than 100-metres high, has performed the lifting. First, the 300-tonne steam drums had to be moved out of the way on a track system and set aside for inspection and maintenance.

“This was a huge undertaking that required more than a yearand- a-half of planning just to get to the execution phase, which was delivered safely and successfully through a high degree of collaboration,” said Rob Hoare, Bruce Power’s vice president of MCR Execution. SGRT’s peak resourcing includes approximately 425 people, including 320 skilled tradespeople with the rest in project management – engineers, technicians, co-ordinators, project managers and quality inspectors.

HYDRO POWER

Hydro power entails heavy lifts also. Upgrades to Minnesota’s historic Byllesby Dam are expected to double the dam’s power generation capacity to 4.4 megawatts. A crane from Dawes Rigging & Crane Rental, a member of the ALL Family of Companies, was trusted with the critical role of placing the two new generators.

Dawes specified a Manitowoc MLC300 Lattice Boom Crawler Crane with VPC-MAX for the job. This Variable Position Counterweight system actively engages all counterweight and eliminates the need for passive carbody weights. The result is a dramatically reduced transport configuration and better centre of gravity for reduced ground bearing pressures and added capacity.

The VPC-MAX attachment provides capacities similar to wagon- or tray-mounted attachments, but requires fewer components and assembly steps, which reduces setup time and transportation costs.

Terry Hoops, regional sales representative for Dawes, stated these features were critical to setting the 110,000lb (50 tonne) generators. “This was an extremely tight job site,” he said. “Between the dam, the Cannon River, and other buildings on the site, our laydown area was roughly a halfmile away from where we actually had to build the crane.”

The fact that Dawes only needed 11 truckloads to deliver the MLC300 was therefore a considerable plus. “With fewer truckloads, we needed less space for the staging area. That’s less cost for the customer, a smaller footprint, and quicker assembly,” said Hoops. “After delivering the loads to the laydown area, we trucked components to the build site one at a time – first bringing over the tracks, carbody, and counterweights and then the boom sections.” Dawes also brought a 100-ton Tadano GR-1000XL rough terrain crane to assist with assembly of the MLC300.

According to Dawes other similar-sized crawler cranes would have needed up to three times as many loads, increasing delivery fees and set-up time, and would have had a larger footprint requiring additional ground matting. An all-terrain crane that could handle the weight of the job at the prescribed radius would have needed at least double the capacity, it adds.

Configured with 216 feet of main boom and 474,000lb (215 tonnes) of counterweight, the MLC300 offered the right combination of smaller footprint and large capacity to pick and set the two generators. The process took several hours for each generator, as on-site engineers supervised the securing of connections. After completing the lifts the remaining connections were finalised.

Community leaders in Cannon Falls, Minnesota, tout the project as the first in the nation to generate more electricity through renewable resources than will be needed by the local community. It enables the dam to produce clean power more efficiently and more reliably, with excess electricity expected to be sold to help offset the project’s cost. The job was a joint effort of Dakota County, The Boldt Company, and Xcel Energy.

STORM-DAMAGED STACK

On the other side of the Atlantic, in the UK, power related repair work required the expertise of leading crane hire specialist Ainscough.

In December 2024 Storm Darragh swept through Northern Ireland causing widespread damage. Among the affected sites was a critical component of the region’s energy network, Ballylumford Power Station in Islandmagee. A section of one of its prominent chimney stacks partially collapsed during the storm. Full electricity generation was temporarily suspended. The chimney stack, standing 75 metres tall and weighing approximately 147 tonnes, was severely compromised and at imminent risk of further uncontrolled collapse. It presented an immediate hazard, requiring safe and controlled dismantling. This project presented a highly complex and inherently high-risk undertaking.

Ainscough was entrusted to carry out this highly specialised and critical dismantling operation.

Given the complexity of transporting heavy lifting equipment from the mainland UK to Northern Ireland the operation demanded precise and comprehensive logistical planning.

Ainscough’s Heavy Crane Division, based in Lancashire, brought full operational capability to the site with minimal delay, despite the complexities of distance, cross-border coordination, and potential unforeseen challenges.

Cranes utilised for the work included Ainscough’s Liebherr LTM1500-8.1, its Liebherr LR11000, and its Liebherr LTM1130-5.1.

Due to bridge weight restrictions the Liebherr LTM1500- 8.1 crane had to be partially dismantled to reduce the axle loadings for transporting over the last three miles to site. Over the course of the project more than 100 transport units were required to move the crane components and associated equipment safely and efficiently.

The precarious condition of the stack demanded exceptional precision, stringent safety measures, and highly controlled dismantling procedures to mitigate danger to personnel, the powerplant and the surrounding environment. Operational urgency was of the essence given that one stack and section of plant would remain offline until full repairs could be completed.

Limited accessibility and the scarcity of suitable areas for a large-scale crane operations added still more complexity: extensive preproject planning and groundwork were needed. And operations had to be carefully coordinated around the notoriously harsh Northern Irish winter conditions, particularly high winds and unpredictable weather patterns.

Ainscough’s project team devised a meticulous and adaptive lift strategy, tailored to the site’s many challenges and evolving conditions. For its strategic crane deployment it mobilised a robust fleet of heavy lifting equipment. The Liebherr LR11000 1,000 tonne capacity crawler crane provided the necessary lifting capability at a 75m radius to respond effectively in the event of further structural collapse. The 500 tonne Liebherr LTM1500-8.1 mobile crane gave safe access to the stack for cutting and dismantling operations using a man basket. Given the limited access this crane was also used to assemble the LR11000. The 130 tonne Liebherr LTM1130- 5.1 mobile crane supported the placement of over 30 7.5x 2.2m heavy duty steel mats and assisted in the latter stages of the Liebherr LR11000 assembly.

Rigorous ground preparation was needed. An area of grass and shrubland had to be transformed into an area capable of supporting the loads imposed by all cranes.

The client, EPUKI, led the groundworks which involved the removal of approximately 400,000 tonnes of spoil followed by systematic layering and compaction of new material.

Throughout the process bearing capacity tests were conducted at key stages to ensure stability. The final crane pad comprised over two metres of engineered fill designed to safely support the heavy lifting operations.

Given the precarious condition of the stack, safety was of utmost importance. The client implemented a laser monitoring system that tracked movement at three key points on the stack, providing a comprehensive visual representation of its behaviour.

“What was particularly interesting, and unusual, was that while we anticipated movement in the direction of potential collapse, the laser revealed a 21mm shift in an uprighting direction when strong winds blew from the opposite side,” said project engineer and appointed person Igor Scalas. “No movement was detected toward the fall direction.”

Situated as it is on the Northern Ireland coast the site frequently experienced strong winds exceeding 25m/s, which presented a significant challenge.

Most of the work was conducted at height using man riders at 75m. Operations were therefore restricted to wind speeds below 7.0m/s for safety.

Continuous monitoring was carried out by all parties and cross-referenced across all three cranes, enabling the lift team to better anticipate acceptable wind conditions. Daily coordination meetings were held to assess weather forecasts and agree on safe work windows. The team remained flexible, adjusting their plans to capitalise on suitable weather windows and ensuring safety was never compromised.

Despite significant risks and harsh winter conditions Ainscough Crane Hire successfully completed the dismantling operation within a tight seven-week schedule, including both rigging and derigging phases.

The project was completed without a single safety incident.

“This was among the most technically and mentally demanding lifts our team has ever undertaken,” said Dave Baxter, senior technical manager at Ainscough Crane Hire. “The severe winter conditions and the inherent risks required us to maintain unwavering focus and cohesion throughout. I’m immensely proud of the team.”

Thus Ainscough delivered a critical solution to a highly complex and high-risk industrial project that safeguarded the site and paved the way for the full restoration of a vital asset in Northern Ireland’s energy infrastructure.

From nuclear refurbishment in Canada to storm damage recovery in Northern Ireland, and from deepwater decommissioning in the Gulf of Mexico to hydro upgrades in Minnesota, these case studies underscore the central role heavy lifting plays in today’s evolving energy landscape.

Whether enabling the safe retirement of aging fossil fuel infrastructure or supporting the development of more sustainable and reliable power sources, lifting operations – often executed under extreme conditions – demand not only technical precision but also logistical creativity, engineering innovation, and unwavering commitment to safety.

As the global energy sector continues to adapt, decarbonise, and modernise, the lifting industry’s contribution remains as essential as ever – lifting not just loads, but the future of energy itself.