If any sector of the crane world is expanding faster than any other it would seem to be the mini crane. Makers are opening new dealerships all around the globe at a rate that it is hard to keep up with.

The cranes themselves are evolving as well. Simplicity of operation and of technology is, perhaps paradoxically, giving way to extreme simplicity of operation and almost as extreme sophistication of technology.

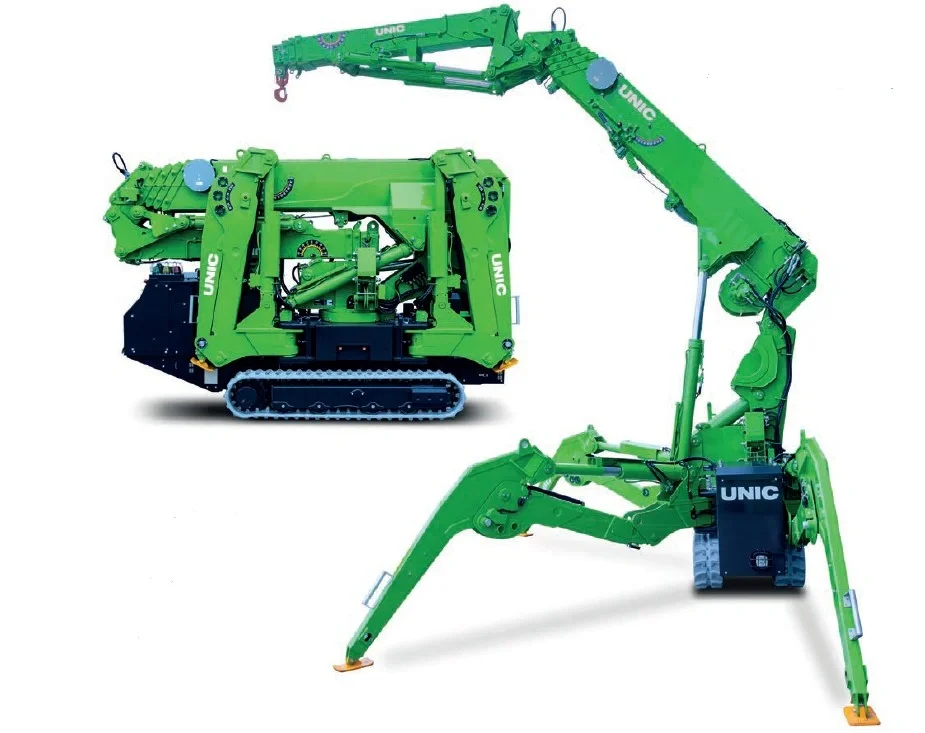

There have been changes in geometry as well. The spider crane was a wonderful innovation… but is no longer new. A recent development of it has been the pop-up crane. It does what it says on the tin: it is a spider crane on tracks; when it has reached its workplace the legs extend, as before; then, and here’s the evolution, a kingpost rises from the chassis (there used to not be kingposts), the boom then unfolds from the kingpost, and everything follows from there.

This July UK-headquartered lifting solutions provider GGR Group introduced the new UNIC UM325 pop-up. GGR is the UK agent for UNIC and has long been a pioneer of the mini crane.

The new machine is powered by a lithium battery pack which can charge while in operation. Emissions-free operation for indoor working is, of course, one of the well-known advantages of the mini crane. The UM235 has a 2.9 to 10.0 metre main boom and, a new feature, a fully hydraulic telescoping luffing jib/searcher hook attachment. The new luffing jib has a maximum capacity of 1000kg, extends from 2.0 to 5.7 metres, and has a luffing range from -10° to 80° offset. The enhancements enable the UM325 to achieve lifting heights of up to 17.8 metres and a maximum working radius of 16 metres.

Dan Ezzatvar, marketing and special products director at GGR, explains its genesis: “We introduced the prototype at Bauma in 2022, just before the pandemic. Maeda launched its equivalent soon after. It is significant that both of those are Japanese makers; they introduced the type in response the success of European-manufactured cranes. The Japanese had been very much the pioneers of the mini crane, and they were well-built and simple to operate. European manufacturers, such as Jekko and Hoeflon, then produced their own mini cranes that were definitely not like-for-like copies. The European cranes were very intricately designed, and very versatile. They had, for example, integrated fly jibs as standard. For that reason you can do a lot with those machines; and integrated fly jibs is something that the UNIC and Maeda machines did not have.

“As you can imagine, feedback from our dealer network highlighted this difference and so there was a genuine business case for the Japanese to bring out a more versatile crane.

“As a result, since the Bauma 2022 launch, we have been focussing on the production models of the pop-up crane; we have also been focussing on the introduction of hydraulic fly jibs. Specifically, we have a new fly jib for the UNIC 295 machine, and we also have one for our pedestrian operated 546.”

The UNIC URW 295-3 spider crane has a lifting capacity of 2.9 tonnes (at 1.4 metres) yet a width of just 0.6 metres – so it can fit through a standard door frame. It has a maximum lifting height of 8.8 metres, which increases to 9.8 metres with the new fly jib, and 10.47 metres with the fixed hook.

It is petrol-powered, with the option of LPG dual, electric dual, or diesel. Radio remote control comes as standard and the URW-295-3 has variable adjustable outriggers, allowing it to operate around fixed obstacles on the site and reducing the working footprint of an already compact machine.

The UNIC 546 has a larger lifting capacity of four tonnes (at 2.5 metres) with a maximum working radius of 15.52 metres.

BRIDGING THE GAP

Another new and interesting machine of which GGR is UK distributor is the T-crane 1060 made by Italian company Almac. “We became the company’s UK dealer recently,” explains Ezzatvar.

It is on rubber tracks and can be driven on slopes up to 25 degrees, while its self-levelling ability enables it to work on slopes with up to a 15° angle – giving operators adaptability over rough terrain. You could perhaps call it a cross between a rough-terrain crane, a teleboom crawler, and a mini crane with aspirations.

“What is interesting about this machine,” says Ezzatvar, “is that with it Almac has bridged the gap between the mini crane market and the materials handling market.

“It has the chassis of a tracked carrier machine and, because these need to keep the load flat while going up steep inclines, it has self-levelling technology. That technology wasn’t initially developed for lifting or even carrying loads. It was developed for man-riding – which means that it has a great deal of safety-related legislation behind it.

“So Almac had this simple-tooperate machine that was born out of access industry. We talked to the company, and it came up with a version that was smaller but more capable. These things are like little tanks now. They really do perform well on site.

“And when you add the idea of putting a crane on it, you have something totally new. It is the only machine I know of that has pickand- carry capability while it can self-level – and it has all the safety features of man-carrying already in the design. The configuration has bridged the gap between materials handling and lifting.”

The T-crane 1060 is powered by either a 300Ah lithium battery pack or, alternatively, a Yanmar diesel engine. It has a 7.7 metre lifting height and a 6.1 metre maximum working radius. It is supplied with a radio remote control as standard and can lift and transport weights up to 990kg.

A 1000kg counterweight is detachable; with it removed the overall weight can be reduced to 2850kg. This makes the T-Crane 1060 simpler to move by trailer or to work on job sites with extremely low ground pressure.

For another example of a mini crane hybridising with other types witness the new Jekko JF235, which was unveiled in January. Jekko claims it as ‘a technological revolution’ and as a ‘chain link between truck cranes and mini cranes.’ It is an evolution of Jekko’s JF series (which comprises the JF365, JF990 and JF545); it is the smallest of the series but, Jekko says, the richest in new features.

Among the design changes the counterweight, previously located externally on the rear of the crane, is now built in the frame. This eliminates the space occupied by the rotating turret at the back of the machine. This model is fitted with four independent stabilisers directly controlled via the remote control. Each stabiliser is equipped with a double extension and can rotate by 0° to 45°.The stability level is calculated automatically and displayed both on the remote control and on the onboard screen. The result, Jekko says, is maximum stability and safety.

Power is bi-modal. A Euro 5 1.5-l diesel engine has an intelligent electronic system that adapts the revolutions to the requirements of the hydraulic system. This, Jekko explains, means it provides very low consumption. A larger 52-litre tank allows for longer operation times.

The mini crane also has a cablepowered 13.5-kW electric power pack which lets users operate in full electrical mode in indoor locations and public places. A new user interface displays stability, crane, engine and diagnostic data on a seven-inch water- and dustproof touchscreen.

The electro-hydraulic system is, Jekko claims, cutting-edge technology. The modular hydraulic pump has optimised control of both oil pressure and capacity. This is designed to gives maximum precision combined with speed.

An independent electric cooler keeps the oil operating temperature at around 40° with the aim of extending machine performance and duty cycle.

The entire system is fully designed and developed by Jekko.

GAME CHANGER

Japanese manufacturer Maeda also has a new model which it claims is a ‘game-changer’. The model is the MK3053-C. The man making the claim is Andy Crane, sales executive of Kranlyft, which is Maeda’s UK agent and distributor.

“This is the second knuckleboom produced by Maeda,” he says. “It has been in preparation for two years. It has 17 metre lifting height and weighs 2900kg – so it can be put on a trailer; to have a trailerable machine with that height of lift is quite something. We are working with a design company on a trailer specifically for it that will take the crane and all its attachments in one. It will have a cover as well, to keep the machine clean, and that can be customised with the client’s logo. It is certainly true that trailering keeps costs down compared to transporting on a truck.”

Four falls on the MK3053-C give it 2980kg capacity at 1.8 metres; the fly jib and fixed search hook has two offsets. The outriggers are stepless, so they are fully variable. This, of course, helps in confined spaces; they are fixed by brakes, not pins.

“The difference between this machine and the opposition is quality and reliability,” says Crane. “You have only to look at it to see that it is built very well; it’s built to last. Look after it and you will get over 20 years of work from it with no trouble at all; and you will also get a good resale price if you sell it.

“It is designed to be easy to use. One-button outriggers, one-button levelling, one-button stowing when the job is finished… removing the hydraulic jib is a one-man operation, too. The crane uses the outriggers to lower the fly jib to the ground, which is very crafty indeed. Once on the floor the jib is on castors, so it is easy to move around. All that the operator has to do it unpin it and roll it away. No tools are needed. It is very easy to set up as well.

“The first one was ordered from us by Phil Hird, of Hullheadquartered Hird Crane Hire more than two years ago; he placed the order just on the rumour of a new Maeda machine. We didn’t know then what the product would be, its capacity or size, but he said ‘I’ll take one!’. Then he upped his order to two, and he has told us that when he has evaluated the MK3053-C and seen how it fits in he might well buy more. Hird has over 80 Maeda machines and 20 of the Maeda Eco cranes. This year alone the company has bought six more Ecos. With the two MK3053s that makes eight new purchases this year alone. So clearly there is demand for these cranes, and work for them, too.”

The MK3053C is available in three versions including a standard diesel machine, a diesel electric option and a full lithium battery electric battery version. Remote control is standard

“The eco machines come with a swappable battery pack,” says Crane. “They can be charged while operating and, in general use, will last all day on a charge. If the jobsite has no access to power yet you need more out of the crane then the discharged battery can be taken out and a charged spare one plugged straight in.”

So there are game-changers, there are cross-overs, there are pop-ups; there are diesels, there are plug-ins, there is batterypower, there are hybrids; and if the choice is growing more complicated, they are all of them becoming simpler to use. Take your pick.

DEALING OUT DEALERSHIPS

Makers of mini-crane makers are well aware of the growing acceptance of, and demand for, their machines and are responding to it. This is not just with new models; they are expanding their dealerships worldwide, too.

Last year we reported that Maeda had just opened an American branch, Maeda America Inc., with the aim of penetrating that market which had been slow to catch on to the utility of mini cranes. Since then Maeda America has been establishing an entire network of dealerships across North America.

Dutch manufacturers Hoeflon has also announced a new dealership, this one in the UK. On 1st July, Hoeflon UK was created, as part of the Crowland Cranes Group. Crowland Cranes is one of the leading hire and sales companies in eastern England; and the new setup makes it the UK distributor for the complete Hoeflon B.V. compact mini crane range. At its head office in Peterborough Crowland has built a new demonstration area where clients can test each model within the Hoeflon range, including attachments such as lifting beams and glass handling equipment. Crowland celebrated the day by delivering its first Hoeflon sale from the new range, a new C10e, sold to its long-standing client, City Lifting, and sent straight to London.

But probably no manufacturer can rival Italian crane maker Jekko in the sheer speed and number of new country dealership appointments. Headquartered in the Veneto region, in the north of the country, the company has experienced five straight years of growth; and since the start of 2024 has recruited dealerships around the world at the pace of one or more a month. “It is a confirmation of our corporate commitment to be present worldwide with a countryafter- country conquering strategy,” says sales and marketing director Alberto Franceschini.

Jekko began the year in February by recruiting Foster Cranes as its exclusive UK agent: Foster Cranes is based in Kidderminster. The same month Jekko appointed a dealership in Ecuador, Bagant Ecuatoriana, which has two well-managed rental and sales lines and has been a reference provider for the Ecuadorian market for over 40 years. In March Jekko appointed Simeri Oy as its dealer for Finland and Estonia; and, in the same month, it turned to South Africa and selected Skyjacks as its exclusive dealer for their products there. “Skyjacks first visited us seven years ago,” explains Franceschini, “but at that time Jekko’s size, organization, machinery, and quality were not up to the level of a major player like SkyJacks in South Africa.” That was then, this is now. “It is personally satisfying to see that, after all this time, SkyJacks has witnessed the incredible growth of Jekko on the international markets, in its organisation, in products, and in quality – which is why it was finally easy to choose it to distribute for us.”

In April Jekko’s focus turned to Norway, where Correct Maskin became the official Jekko dealer for the country. Correct Maskin has been telehandler specialists for a number of years; this, says Franceschini, is significant and part of the reason for its appointment. “The telehandler world is a much more mature sector than that of mini cranes but with many common and complementary areas, never in competition. It is a symbiotic business model which allows the distributor to specialise in the lifting sector with a wide range of products for a vast offering in the market. The agreement with Correct Maskin focuses on this aspect.”

Franceschini’s comments resonate with those of GGR Group’s Dan Ezzatvar, quoted in the main article, on how the T-crane 1060 addresses both markets. Perhaps we are seeing the distinction between telehandlers and mini cranes starting to erode?

Next in Jekko’s expansion strategy was, in June, to appoint an exclusive dealer for Slovakia and the Czech Republic in the form of Kolex, which now offers complete sales, service, and technical consulting for the whole Jekko range.

“The year 2024 is bringing great changes for Jekko, mainly in terms of products and of dealer network organisation,” summarises Franceschini. “We’re penetrating several new markets and reorganising others where we’ve been operating for several years now. Our products in the past years have been dedicated to advanced operators. Now we have completely renewed them to become extremely user-friendly and to offer a more accessible experience to a larger number of operators. The entire SPX range, as well as the MPK and the JF product families, have undergone an innovation phase inspired by this philosophy. As a consequence our market approach has also been upgraded.” In other words, the cranes are even easier to use and more dealers can promote them accordingly. Watch this space for further expansion stories…

ITALIAN STYLE: VENICE RENOVATION

Back at the beginning of 2024 a three-storey private residence near Venice undergoing renovation presented a challenge. The entry space was a narrow stairwell only six by six metres. Traditional lifting equipment would have struggled to access the site without compromising existing masonry and interior finishes. The task involved lifting and installing steel staircase modules without spoiling the finished ceiling or other parts of the house.

A Jekko SPX328 mini crane, rented from Kiloutou, emerged as the optimal solution. Its compact dimensions allowed it to pass through standard doors (80 cm wide) and to position itself strategically inside the stairwell. This placement enabled its vertical boom to extend precisely, lifting and manoeuvring the staircase modules into position for installation.

The crane’s compact build facilitated easy entry into confined areas, navigating through narrow hallways and doorways without spoiling the building’s interior finishes. This capability ensured material placement while maintaining the structural integrity of the renovated space.

The SPX328’s ability to handle heavy loads significantly reduced manual labour requirements, says Jekko. This efficiency not only accelerated the installation process but also enhanced overall project productivity, reducing downtime and costs.

Advanced stabilisation systems and precise load monitoring were crucial in maintaining safety; the crane operated quietly and with zero emissions on its lithium-powered battery system, allowing indoor use without additional ventilation. Various attachments assisted diverse construction tasks; intuitive controls and remote operation capabilities ensured ease of use, allowing operators to manage the crane efficiently with minimal training.

The SPX328 exemplifies a paradigm shift in indoor construction methodologies, claims Jekko, particularly for projects requiring precise installations in confined spaces. Contractors can leverage advanced technology to optimise efficiency and safety while achieving great results in complex indoor environments.”