Countries across Asia are proving to be an ongoing source of highrise job sites, infrastructure builds, and prestige projects. As such these markets remain strategically important to tower crane manufacturers.

The Bauma China show, which took place 26-29 November, in Shanghai, China, provided the perfect opportunity for manufacturer Manitowoc to launch the largest topless tower crane in its Asia range: the 80-tonne capacity Potain MCT 2205.

The crane has an 80-metrelong jib which can carry a payload of 23.5 tonnes and is being built at Manitowoc’s Chinese facility in Zhangjiagang.

Manitowoc says the new model offers similar performance levels to the largest Potain hammerhead cranes, whilst making features of flat-top designs available. These, it says, include simplified transport, ease of assembly, and a more compact profile.

Despite being Zhangjiagang’s largest crane the top-slewing portion of the MCT 2205 M80, including all 11 sections of jib, can be transported in 16 trailers or containers. The crane’s wellproven mast telescoping system is constructed for Potain’s R99A or R910A mast sections.

The crane can achieve a 71m height under hook with PA950 fixing angles, or 99.9m with PA952 fixing angles. It can carry a 23.5t payload at the end of its full jib configuration, with its maximum 80t capacity available between 5 – 26.3m. This extends to 30.5m when the jib is built to 45 or 50m, while 72.9t can be handled towards the end of a four-section, 30m jib assembly.

These capabilities are designed to help it deliver heavier loads further across busy jobsites, whilst reducing impact on the operation of nearby cranes, says Manitowoc.

With up to 124,000 kg of ballast available the MCT 2205 comes with two counterjib options – the full 25.2m or a 20.2m design depending on jobsite requirements.

The crane’s hoisting winch is a 280 LVFC 200 Optima. Supplied with 1,007m of rope, its 280 hp/212 kW motor enables an 80t load to be raised at a speed of up to 12m/min.

This same payload can also be propelled horizontally at adjustable speeds up to 25 m/min by the 25 DVFC 35 trolley’s 25 hp/18.5 kW motor. Four RVFC 194 Optima+ slewing motors govern the rotation of the upper structure. The crane is controlled from Manitowoc’s V140S Vision Cab.

“Manitowoc has leveraged its decades of expertise in developing large-capacity tower cranes to design a topless crane that meets our customers’ lifting requirements in this new era of construction,” says Kwong Joon Leong, regional product manager at Manitowoc. “We are already seeing a great deal of interest from those working on large infrastructure projects, power plants, and other mega projects that require the lifting of very heavy loads.”

DEALERSHIP NEWS

Further cementing its presence in the Asia Pacific region Manitowoc has appointed NFT Hong Kong as its new official dealer for Potain cranes in the market. NFT Hong Kong is part of the wider NFT Group Asia which includes NFT Taiwan and other subsidiary businesses across the continent.

“Hong Kong is a lively and vibrant market, but also highly competitive, so it’s important for Potain to have strong representation in the territory to maintain its industry-leading position,” says Jean-Francois Amet, sales director at Manitowoc. “We are delighted to have our trusted partners at NFT offering sales, rental, and customer service to customers across Hong Kong.

“We’ve already seen a very positive reaction from the market, and we believe both Potain and NFT will benefit greatly from this new partnership.”

NFT Hong Kong has a rental fleet of 40 Potain tower cranes, in addition to offering sales to contractors and other rental companies. Given Hong Kong’s distinctive skyline with tightlypacked high-rise buildings, Potain’s luffing jib tower cranes have been popular in the market for quite some time. Models like the MR 418, MR 608, and MR 618 from Potain’s European offerings, along with the MCR 625 from the Asia range are commonly utilised on projects and rental fleets throughout Hong Kong.

ITALIAN STYLE

In Europe manufacturer Terex Tower Cranes has also strengthened its sales and aftersales support for its entire range of tower cranes in its core market of Italy.

The company has signed an agreement with Italian tower and self-erecting cranes rental and sales specialist Mevi for the regions of Lombardy, Piedmont, Liguria, Tuscany and Emilia-Romagna. Effective immediately, Mevi will provide sales and after-sales support for the entire range of Terex tower cranes.

Mevi has been operating in the market for more than 50 years, offering site-specific solutions through its team of specialised consultants and technicians.

“Mevi will be the reference for our product in the regions of Lombardy, Piedmont, Liguria, Emilia-Romagna and Tuscany,” says Paolo di Giambattista, sales area manager Terex. “In these regions with Mevi we intend to increase our presence through the guarantee of technical and commercial support to an increasing number of customers.”

NEED FOR SPEED

Remaining in Europe, manufacturer Liebherr also has a new tower crane on the market.

September saw it launch the 440 HC-L luffing jib tower crane. Liebherr says it launched the crane in response to demand for ever faster construction site cycles.

As a result the new machine offers reduced out of service radius, increased lifting capacity and a shorter assembly time.

The 357 HC-L is available in two versions: the 440 HC-L 12/24 and the 18/36. The maximum lifting capacity of the 440 HC-L 18/36 has increased from 32 to 36 tonnes. It has also been possible to raise the tower height of both crane versions by one tower section compared to the previous model.

The new 440 HC-L has an outof- service position of up to 10.7m and a minimum working radius of less than four metres is possible, enabling it to be setup close to other buildings or cranes.

For the first time Liebherr is using aramid fibre guying on one of its luffing jib cranes. The lightweight material reduces weight on the jib, resulting in a higher lifting capacity. It also offers advantages for crane assembly and disassembly, says Liebherr, due to its lighter weight.

Faster assembly is further facilitated by the use of one central switchgear cabinet.

Electronic components are arranged in a plug-and-play setup, which significantly reduces assembly time.

Assemblies are also preassembled at the factory prior to the crane being delivered, thereby optimising transport costs and enabling the crane to be unloaded more quickly on site. The counterjib ballast, which consists of a single block, also contributes to faster assembly and disassembly. Only nine transport units are needed for the slewing section at full jib length, including its counter-ballast.

The 440 HC-L’s maximum radius has increased to 65 metres and its jib head lifting capacity by up to 52 percent. The jib can be extended in five metre increments. Thanks to Load Plus, performance can be increased by up to 22 per cent at the touch of a button.

With a 50-metre jib, for example, the maximum jib head lifting capacity increases from 7.5 tonnes to 9 tonnes.

Tower heights have also been significantly improved: the freestanding height has been increased by up to 5.8 metres, the maximum assembly height (free-standing) measures in at up to 76.4 metres. This makes planning climbing steps more flexible, says Liebherr.

It is clear the construction industry’s demands for heavier lifts, increased speed and efficiency, and space-optimised solutions are driving innovations in tower crane technology across the board and around the world.

Bauma China has just provided the perfect launchpad for Manitowoc’s new large-capacity topless tower crane in strategic Asian markets; we now wait with interest to see what new metal is launched surrounding Bauma Germany in April 2025.

HISTORIC WORK FOR JASO CRANE IN NORWICH, UK

A Jaso J160.10 saddle jib tower crane, which has been working on Norwich Castle, in the UK, for the last four years was finally dismantled by Morgan Sindall Construction on 25th and 26th November. It was being used as part of The Royal Palace Reborn project.

Since it was erected in September 2020, the 41.5m (136ft) crane has transported all the materials needed for the project from the contractors’ compound in Castle Gardens onto the mound while also removing deconstructed material.

The project will recreate the Norman layout of the Keep, enabling visitors to experience Norwich Castle as it was in its medieval heyday.

Over its four years in operation the tower crane has played a key role in the project. With a seven-tonne weight limit in force on the Castle bridge, it has been the only way of transporting the materials required for the project onto the mound which, as a scheduled ancient monument, needs to be protected.

“Without the tower crane there would be no Royal Palace Reborn project – it’s been central to the complex construction work which will ultimately enable us to recreate the palace of the Norman kings,” says Cllr Margaret Dewsbury, Cabinet Member for Communities, Norfolk County Council. “While those of us who live and work in the city centre have grown used to its impressive presence, it will undoubtedly be nice to have an uninterrupted view of the Castle once more while we look forward to the amazing transformation which it has enabled.”

SEVEN RAIMONDI FLAT-TOPS FOR PRESTIGIOUS DUBAI MASTERPLAN

Raimondi Middle East has deployed seven Raimondi MRT159s to support the construction of one of the Emirate’s most prominent residential districts.

“We are proud to participate in the development of one of Dubai’s most anticipated masterplans by renting seven Raimondi MRT159 flat-top tower cranes to the project’s contractor,” stated Wael Hasan, general manager, Raimondi Middle East.

Hasan, highlighting the characteristics of the crane that made it well-suited to the unique challenges of the jobsite, confirmed that “a positioning and installation study fundamental to maximize machine performances and overall safety” was undertaken prior to choosing the MRT159 for the site.

Situated between other construction sites with a narrow layout, the site posed both logistical and operational challenges. “The ease of installation and commissioning coupled with good lifting performance made the MRT159 an excellent crane to satisfy project requirements, demonstrating its adaptability to tight urban environments,” he added.

Erected between July and October by the Raimondi Middle East operations team, one of the most lauded characteristics of the MRT159s was its arrival onsite with all parts pre-assembled, ropes passed, and rope connections set, thus facilitating smooth field procedures.

The seven flat-tops present jib lengths ranging from 38m and 44m, with freestanding heights of 39m, 45m, and 51m respectively. Boasting a maximum lifting capacity of 8t, the machines are equipped with a 30kW hoisting gear, lifting at a maximum speed of 80m/min and have a drum capacity of 440m.

The new complex will feature 326 units spanned over five-storeys, with the cranes remaining onsite for approximately 15 months.

STAFFORD TOWER CRANE IN THE BAHAMAS

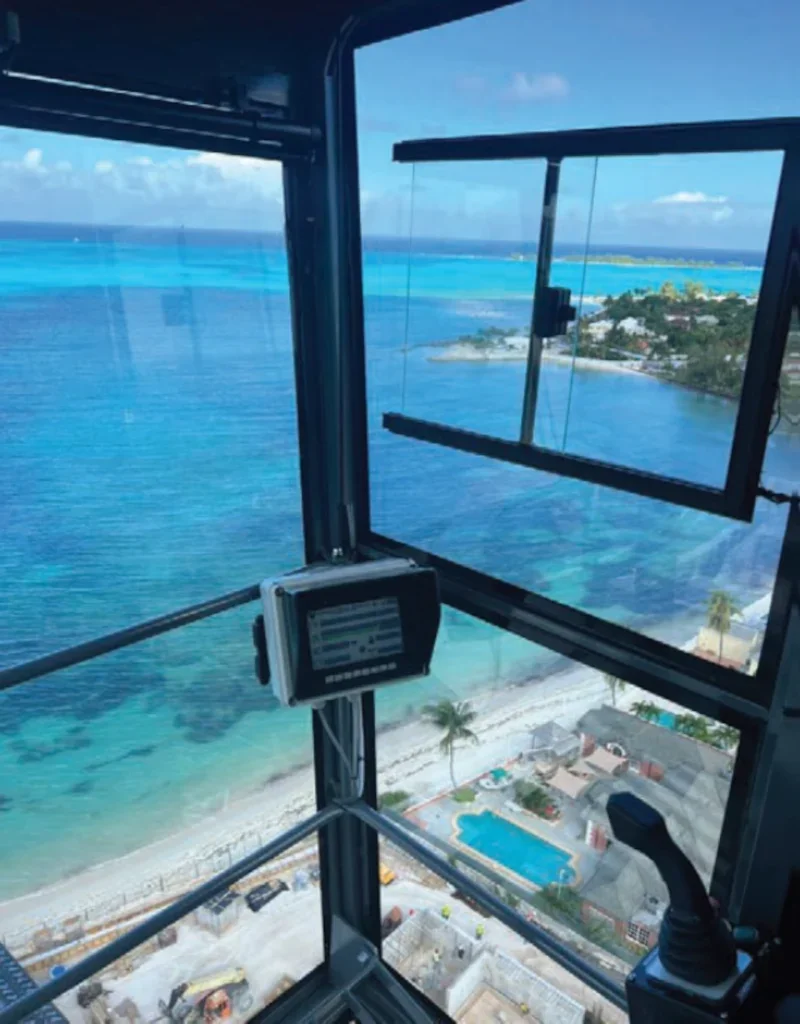

Luxuary Bahamas-based hotel Goldwynn Resort & Residences has taken delivery of a Stafford STF 7022 TL tower crane from Stafford Tower Cranes.

Due to the crane’s location right on the coast Stafford said it had to take into consideration high wind factors. Despite this the crane offers a maximum reach of 230 feet and is capable of lifting up to 5,340 lbs at the tip. Safety and reliability are top of our agenda, says Stafford Tower Cranes.

VEIDEKKE USES WOLFF CRANES IN NORWAY

Norway’s largest construction company Veidekke is utilising five Wolff 7534.16 Clear tower cranes across two job sites in eastern Oslo.

The first site is a residential complex with 180 units where two cranes have been used to transport heavy prefabricated parts, steel and concrete.

Over eight days the cranes were also used to pour five elevator shafts using a slipform construction process. While the formwork self-climbed upwards, each crane poured concrete into one shaft around the clock. This, says Wolffkran, was aided by the crane’s 75 KW hoist winch which provides an operating speed of 185 metres/minute.

At the second jobsite three Wolff 7534.16 Clear cranes are currently constructing Veidekke’s new headquarters just a few kilometres from Ulvenkroken. The building project is characterised by the use of sustainable materials and a modern energy supply. Norwegian Crown Prince Haakon even visited the construction site last year and climbed one of the cranes for a test-drive.