N.C. Nielsen, a Scandinavian supplier of forklift trucks, terminal tractors and special machinery, to develop a completely new type of machine. Named the ‘HH Pick and Carry’ the machine is, N.C. Nielsen says, a hybrid between an SPMT trailer and a crane and is the first of its kind in the world.

The HH Pick and Carry is available with lifting capacities from 200 to over 500 tonnes making it possible to handle heavy loads in areas such as factories, warehouses and ports.

The HH Pick and Carry is designed so that its chassis legs can be shifted in width. This, says N.C. Nielsen, makes it ideal for handling wind turbine towers with diameters up to 8-10 m. It also means it can have a short turning radius.

The HH Pick and Carry can be operated remotely by a walking operator, from the platform or from the cabin for all-weather manoeuvring.

“The new solution is based on requests from the wind turbine industry for very heavy lifting,” says Jørgen Peter Lund, sales manager at N.C. Nielsen. “We’ve focussed on working smarter in less space, despite the goods having grown much larger. So the HH Pick and Carry machines are a natural development in our strategy.”

The HH Pick and Carry is being launched in three basic models: the Tower Mover; the Multi Handler; and the Mobile Straddle Transporter.

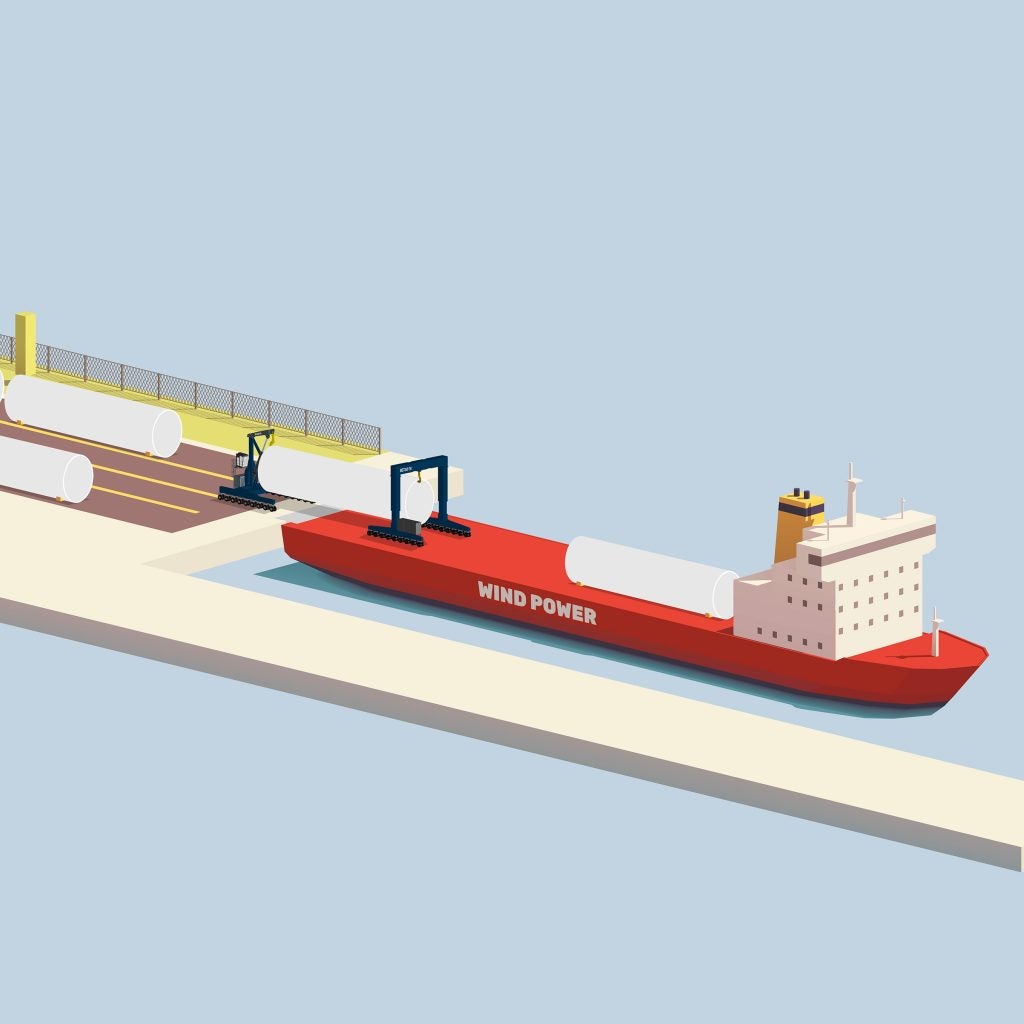

The Tower Mover is particularly suitable for wind turbine towers and elongated structures, says N.C. Nielsen.

The Multi Handler is designed for various single lifting tasks of components for the wind turbine industry such as monopiles, TPs, hubs, bearings and nacelles, but can also be used as one of the components in driving towers.

And the Mobile Straddle Transporter can be used independently for heavy lifting and flexibly in combination with the other two basic models, and this model can run over the entire item if two machines are needed to lift it on board a RoRo ship.

According to N.C. Nielsen a key element the three HH Pick and Carry machines have in common is their flexibility and versatility. “The wind turbine industry has many time-bound projects and mobile lifting machines come with many options and low installation costs compared to stationary harbour cranes, overhead travelling cranes etc. and are relatively simple to move from site to site,” notes Lund. “They optimise logistics and can manoeuvre in a relatively small working space, which is often the reality at a port terminal.”

The HH Pick and Carry can be equipped with optional equipment such as a hydraulic beak, intermediate yoke and special attachments that mean they are suitable for a variety of internal transport tasks. The machines are available as fully electric versions or as a combination.