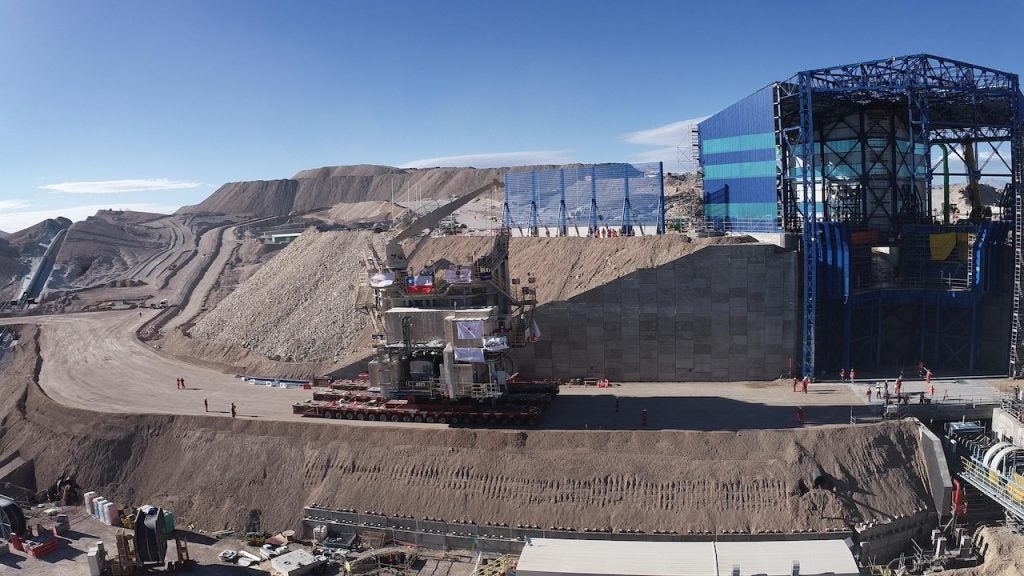

Chilean state-owned copper mining company Codelco commissioned Dutch heavy lift and load specialist Mammoet to move a crusher, and associated parts, a distance of 4.5km across a mine near the city of Calama.

Route-planning for this job alone took a year-and-a-half due to its complexity.

In total 16 components needed to be moved, six of which were particularly large. These were nicknamed ‘the big six’, with the heaviest items being a 1,100-tonne silo and a 1,300-tonne crusher. The crusher was the most complex of the big six to move, says Mammoet, and even required the reinforcement of a support beam to prevent deformation.

The main methodology used for lifting and moving the big six was to lift using climbing jacks and move using SPMTs with support beams, although the exact approach was tailored for each component; some items, for example, also needed to be skidded out of/into position. The crushed also required rotation whilst on route to its new location.

The whole operation took just over a month (faster than expected) and utilised a team of 70 people, and a total of 160 axle lines of SPMT, eight skid shoes (500t), eight jacking systems (400t), as well as support beams, rails, and lashing. It required Mammoet to pool its global resources: SPMTs from Malaysia, skidding systems from the USA, and additional equipment from Colombia were all utilised across the project.