Signed, sealed, delivered

25 June 2018Rui Pedro Faria, senior engineer, Lankhorst Ropes, explains how new certification under DNVGL-OS-E303 can give users of fibre rope slings confidence in the products.

In recent years, oil and gas and offshore energy industries have shown an increasing interest in the use of synthetic fibre rope slings, especially in engineered lifting operations offshore.

Synthetic fibre rope slings offer several advantageous characteristics when compared to steel wire rope (SWR) slings.

The most referenced advantages are lightweight, easy handling and equivalent load carrying capacity (for the same rope size), which translate in significant operational savings, especially when high load carrying capacity (large rope diameter) is required.

However, widespread adoption of synthetic fibre rope slings has been hindered mainly by the lack of understanding of fibre rope characteristics and discard criteria; and because of limited available guidance for the engineering of lifts using synthetic slings.

As reported on multiple industry forums, several rope manufacturers are now committing resources to increasing product knowledge in the market, through product testing, in order to create the necessary confidence.

This confidence will be further increased with a robust product certification, as provided by DNV GL with the DNVGL-OS-E303 standard.

Product certification

Robust product certification under DNVGL-OS-E303 means that the full production process, comprising manufacture, testing, assembly and commissioning, has been reviewed and found to comply with validated requirements. A certified rope sling is important in ensuring greater reliability, durability and extended service life which, in turn, translate into reduced sling maintenance costs, repairs, logistics and replacement.

When fibre rope slings are documented according to DNVGLOS- E303, it is shown they are properly designed, tested and manufactured.

This includes meeting the required quality levels, and is designed to provide the required performance and reliability, while fulfilling the intended application requirements.

This certification process encompasses a comprehensive review of all steps resulting in the final product. The base yarn needs to be approved through the Approval of Manufacturers Program No322, which certifies that the yarn is manufactured in accordance with requirements, and that the production process is controlled (repeatability).

It also includes the review of all the fibre rope production process, through the Approval of Manufacturer Program No321. In this review, all processes, starting from the base yarn reception and testing, initial twisting and all other industrial processes leading to the rope production are evaluated and checked for consistency. After rope production, the sling assembly process is also verified and all the steps regarding Effective Working Length, length tolerances, splicing, and so on, are assessed.

Finally, any tests regarding sling performance, endurance, splice integrity, etc. are reviewed as part of the final certification. Only if everything is in agreement with the both the performance requirements and the standard’s requirements to documentation will the certificate be issued.

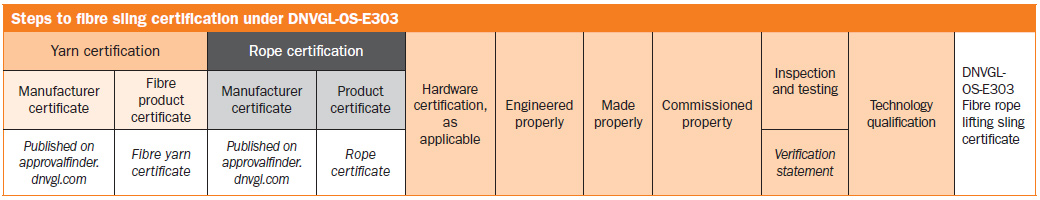

The table on this page shows the schematic representation of the DNVGL-OS-E303 certification process for fibre rope slings. From this certification process, some deliverables (documents) can be extracted, like a Verification Statement for a test that was performed. However, if out of context, these documents don’t provide a meaningful understanding of the slings characteristics or performance.

Why certify?

Buying and using a product that is not properly manufactured and adequately documented as required for E303 certification, although a lower initial investment, will increase the inherent risks of failure, repairs and other ‘surprises’.

A Verification Statement for a proof-load test is not a certificate for a sling product. A proof-load test will attest that a sling has experienced a particular static load, for a certain amount of time, under laboratorial and controlled conditions. This kind of load capacity verification is typically carried out on a total different pin diameter and/ or hardware geometry as compared to the actual real situation and does not consider any other characteristic loads experienced during a real lifting operation (e.g. dynamic loadings), therefore, it is a poor indication of sling performance and reliability in a project scenario.

A Verification Statement only references that an Independent Body has witnessed the sling being loaded to a certain force. No assessment is made to the fibre rope production method or sling assembly. No relevant information regarding base yarn is considered, even if a yarn certificate is available.

This is why a Verification Statement of a proof load cannot be compared to a full and robust product certification, like DNVGLOS- E303, which encompasses all the steps described above.

When selecting fibre rope slings for a next project, please consider the benefits of a full-certified delivery. Consider the material and financial consequences of a ‘surprise’ from a non-certified product, while in the middle of a field operation.

Attend to the trust placed in you by your customer, and only trust properly manufactured and adequately documented products, with the appropriate level of certification.